ASE’s Italian Partner, Sider Sistem is manufacturer of Continuous Casting Measuring Devices. Since over 25 years it has been designing and developing precision instruments for the dimensional control of Continuous Casting Machines. It was born from personal experience in the management of steel plants and from the knowledge of the technical and metallurgical problems of these very complex plants.

MEASUREMENT SERVICES

We offer the expertise and equipment you need to check CCM mould and rolls parameters. Sider can provide on-site mould measurement service for square, rectangular, round, beam-blank and octagonal shapes or slab plates. Segments on-site measurement service includes roll gap, roll alignment and foot-rolls vs mould alignment.

Introduction to mould tube dimensional check

The required high quality of the steel and the increased casting speed need an accurate, frequent and easy check of the mould dimension and his shape. Perform such control in manual way is very expensive, inaccurate and requires too much time. The methodical check of the mould geometry produce immediately the following advantages:

- Prevents quality defects

- Prevents Break Outs

- Optimize the mould life

- Reduce the Mould costs

- Reduce the maintenance cost

- Optimize the Plant Productivity

So, who should be interested in mould tube dimensional check?

- Copper mould tube manufacturers: quality check and certification of new manufacturer mould tube

- Continuous casting machine suppliers: maintenance and assistance operations on managed CCM plants

- Steel makers: Monitoring of used mould tubes or quality check of new tubes

Sideralpha Sistemi, following his long experience and know how in mould measurement, has developed some Mould Measurer in order to make such operation more easy accurate and economic.

Benefits of mould tube laser scansion

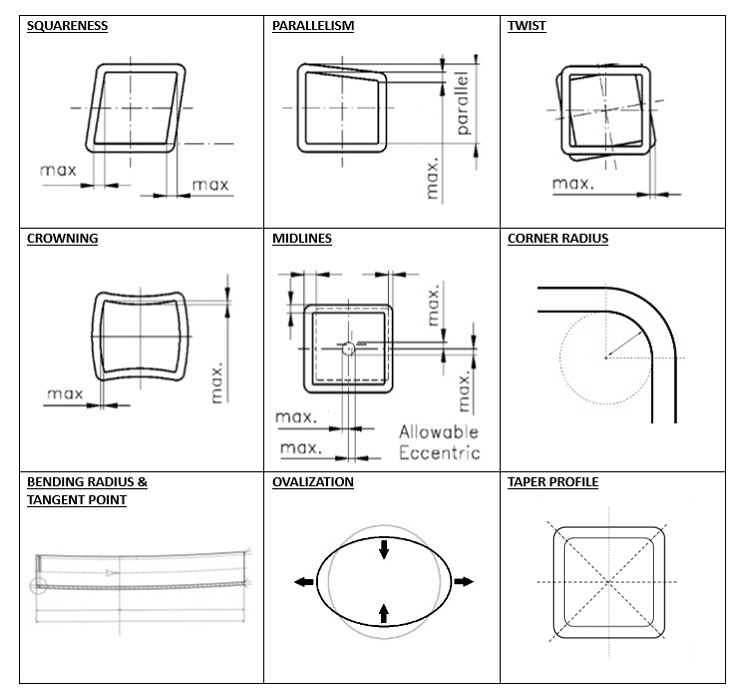

The state of the art in mould measurement has moved from mechanical contact probes to laser technology. The most important benefit is the contact-less and 360 degrees measurement. The full scansion of moud tube internal geometry allows a complete check-up of the tubes, not only the taper profile. Some controls are specific to the mould tube shape (ex. ovalization for round tube). In the following table all the available quality controls are shown: